TECHNICAL SPECIFICATIONS

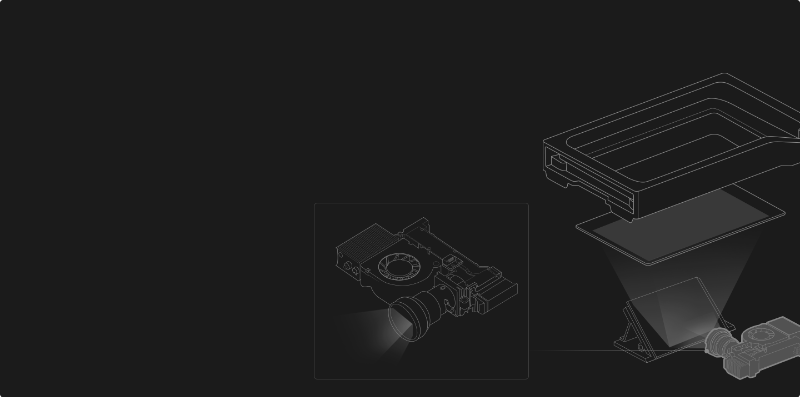

| Print Technology: | Digital Light Printing (DLP) |

| Build Size: | (W × D × H): 200 × 112 × 300 mm (7.87 × 4.41 × 11.8 inch) |

| XY Resolution: | 2560 x 1440 |

| Max Part Weight: | 10 kg |

| Max Printing Speed: | 25 mm/h (0.1 mm per layer) |

| Layer Height: | 50-100 micron |

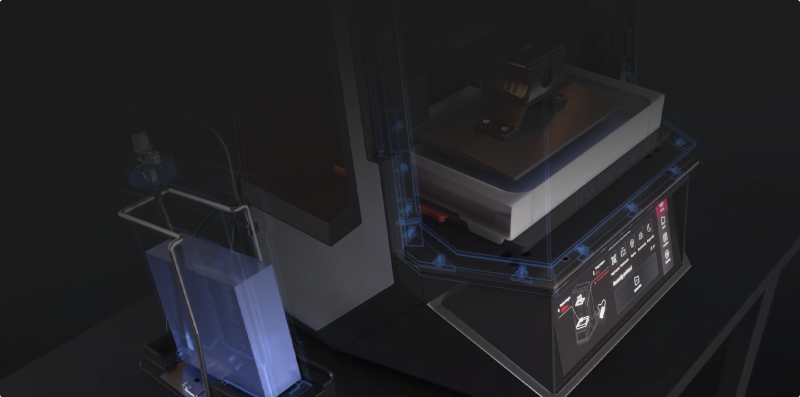

| Resin Management: | Auto Resin Feeding, Resin Level Detection, Resin Confirmation |

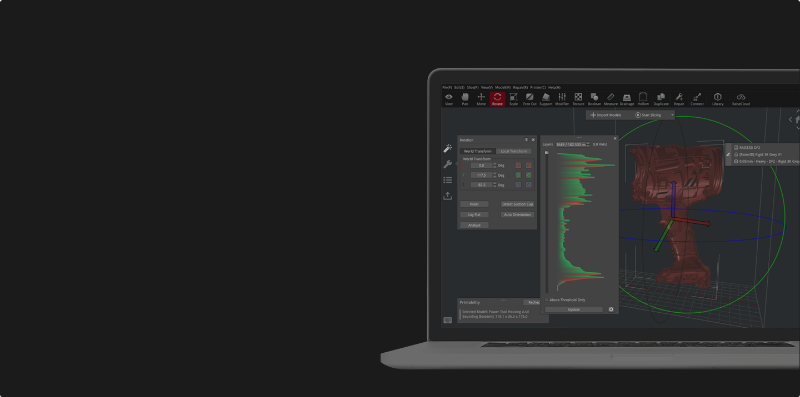

| Control Panel: | Touch Screen (Resolution: 1920 × 720) with Magic Layout (Allow to easily adjust the print layout and duplicate prints) |

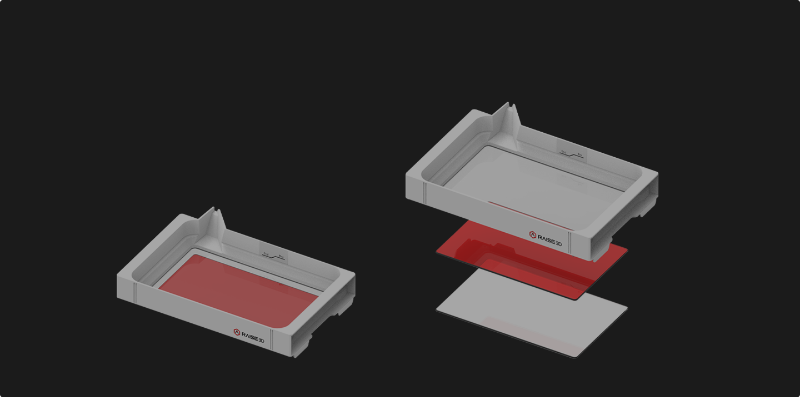

| CRFID Print Platform: | Record the type of resin used and the printing, washing and curing settings |

| Level Calibration: | Calibrated in factory |

| Chamber Heating: | Max 40℃ |

| Raise3D Resins: | Raise3D Standard White Resin, Raise3D High Detail Apricot Resin, Raise3D Tough 2K Grey Resin, Raise3D Rigid 3K Grey Resin, Raise3D High Clear Resin (Coming soon), Raise3D High Temperature Resin (Coming soon) |

| Co-branding Resins with BASF and Henkel: | LOCTITE 3D IND405™, LOCTITE 3D PRO476™, Ultracur3D® RG 3280, Ultracur3D® RG 1100 B ORP |

| (Open Resin Program): | Coming soon |